- Overview

- Our Focus

- Locations

- Contact Us

- Overview

- Our Culture

- Careers

- Jobs

Linglong Tire, headquartered in Zhaoyuan, Yantai, Shandong Province, is a professional and large-scale tire manufacturer, with its products sold to more than 180 countries and regions around the world, and will expand its business to European market in the future.

While Linglong Tire firmly occupies the existing market, it is fighting to kill the incremental market and globalization is unstoppable. When its existing inventory management model cannot support the rapid development of the company, Linglong Tire urgently needs a flexible, transparent and rigorous warehouse management system to replace the old "big book" management model and improve management efficiency and accuracy.

At this time, based on Linglong's refined management needs and complex and changing business scenarios, HAND WMS team combined HighJump WMS products and HAND's self-developed HWMS software to create a set of configurable and simple products for Linglong.

The product is highly configurable and simple to operate, and strictly controls every tire in the whole process, helping the company further expand its intelligent manufacturing scale and enhance its comprehensive competitiveness.

Based on the warehouse management projects implemented by the HighJump WMS+HAP product, the HAND WMS team understands the customer's needs and develops detailed solutions, and has so far completed the first phase of project implementation and smooth operation in many factories around the world.

The scope of implementation covers 6 factories at home and abroad, with more than 80 warehouses in total; the types of warehouses include ordinary warehouses and fully automated three-dimensional warehouses; the types of materials are up to more than 600 kinds, with various management modes; the business types include production, procurement, sales, inter-organizational transfer, etc.

HAND WMS team designs multiple management modes for different warehouse types, different business scenarios and different kinds of Linglong Tire, and Linglong Tire can switch flexibly according to the management level of each warehouse.

The barcode of Linglong Tire was about 80 million at the beginning of the online period, with daily increment of about 200,000 and 700+ concurrent users.

HAND team designed hundreds of millions of warehouse data management solutions and functions in advance during the solution stage, and the time of each factory operation using PDA query and business processing was within 0.5 seconds, which ensured the stable operation and business execution efficiency of the system on the basis of increasing data volume.

HAND team digs deeply into the user needs, pays attention to the end-user operation experience, and continuously optimizes the operation interface, so that even the first-time users can quickly get started;

For different regions at home and abroad, different levels of warehouse management and different business maturity, the system can better meet the requirements of on-site operations and achieve efficient and accurate business operations; at the same time, it can realize the leadership's control of the entire aggregated data.

HAND team designed a complete lifecycle management and traceability process for Linglong tires, and a shipping and warehousing rules program, which restricted multiple layers of control on "problem tires" and solved the pain points of difficult shipping control and traceability of Linglong tires, and increased the accuracy rate from 90% to more than 99.8%.

It also reduces the time spent in constant commuting between the field and office as well as offline communication, saving clients a lot of time costs.

The implementation of WMS project optimizes the information transfer process from workshop to warehouse, improves the efficiency of information transfer and feedback, sorts out the operation process between other business departments and warehouse, and breaks the barriers between systems to achieve efficient connection;

At the same time, it promotes the establishment of Linglong Tire's internal management process specification, from production to warehouse, from procurement to sales, exposing the original management defects and helping Linglong Tire to solve more than 30 management problems outside the project.

In such a severe market environment, the internationalization of Linglong Tire is still unstoppable. The implementation of Linglong Tire WMS truly realizes the planable, monitorable and traceable management of each tire, which provides a solid and powerful backing for the continued expansion of Linglong Tire market.

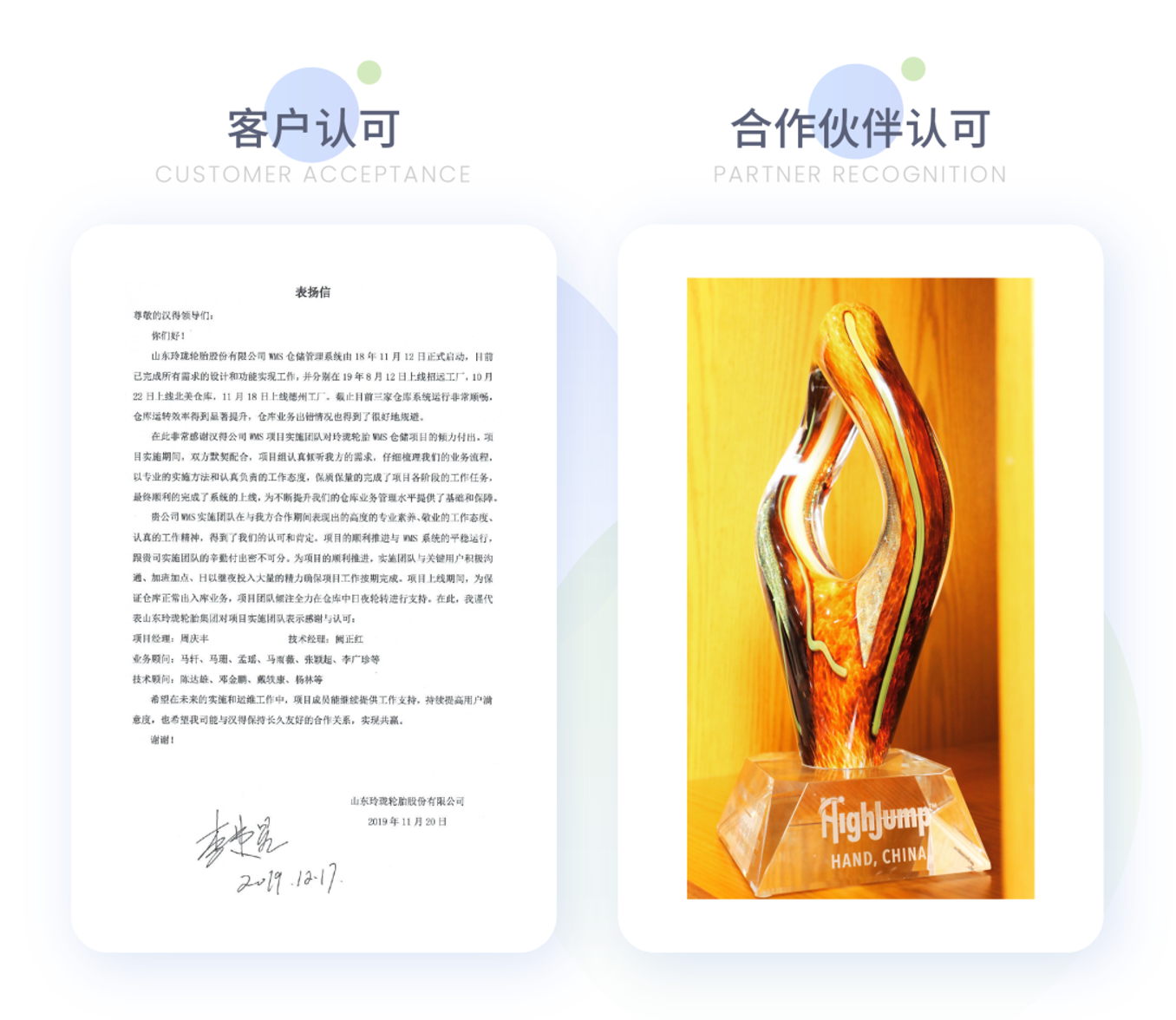

HAND's industry value is thus reflected. The HAND WMS team has gained a lot from this project, not only enhancing the implementation capability, accumulating industry experience and achieving new breakthroughs in technology, but also gaining high recognition from customers and partners.

In the future, HAND team will continue to assist Linglong to build a more corporate, high-quality, efficient and reliable warehousing system to escort the stable and rapid development of Linglong Tire!